à¤à¤²à¥à¤¯à¥à¤®à¤¿à¤¨à¤¿à¤¯à¤® à¤à¤¨à¥à¤¡à¤¾à¤à¤à¤¿à¤à¤ सरà¥à¤µà¤¿à¤¸à¥à¤

Price 30000.00 आईएनआर/ Tonne

à¤à¤²à¥à¤¯à¥à¤®à¤¿à¤¨à¤¿à¤¯à¤® à¤à¤¨à¥à¤¡à¤¾à¤à¤à¤¿à¤à¤ सरà¥à¤µà¤¿à¤¸à¥à¤ Specification

- Corrosion Resistance

- High

- Process Duration

- 1-7 days as per requirements

- Form

- Customized

- Location

- Pan India

- Layer Adhesion

- Excellent adhesion and durability

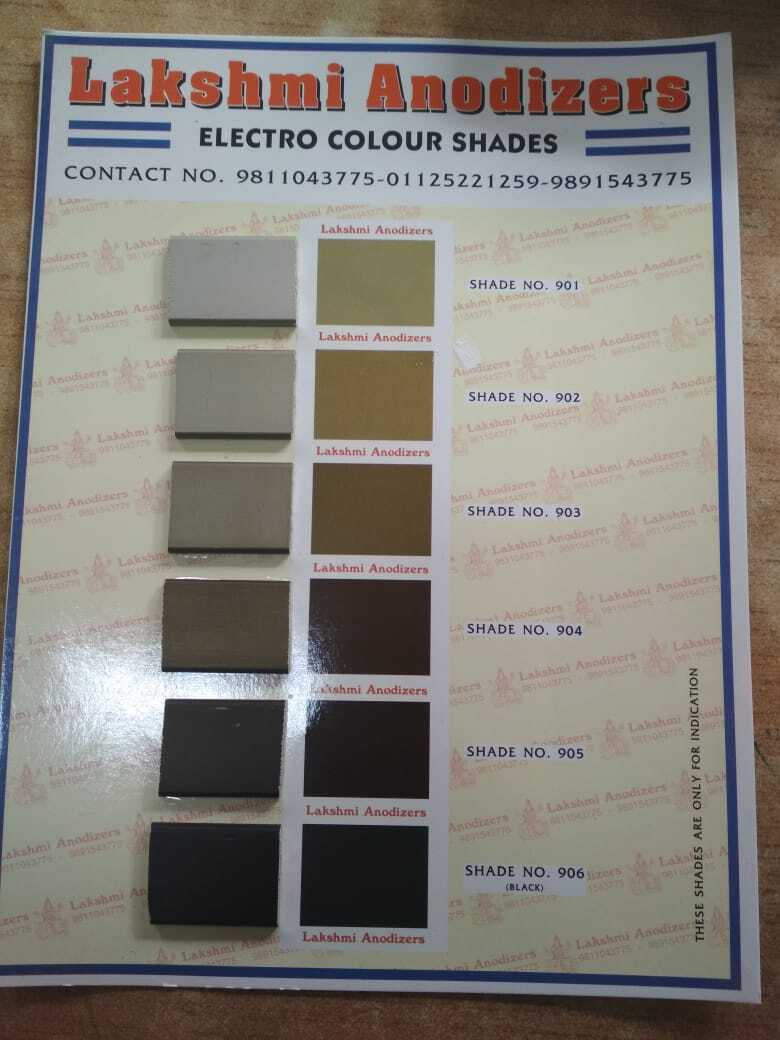

- Color Options

- Natural, Black, Gold, Bronze, Blue, Red (on request)

- Service Type

- Aluminium Anodizing सेवाएं

- Maximum Component Size

- Up to 3 meters (as per facility)

- Application

- Architectural, Industrial, Automotive, Electronics, Decorative

- Finish Type

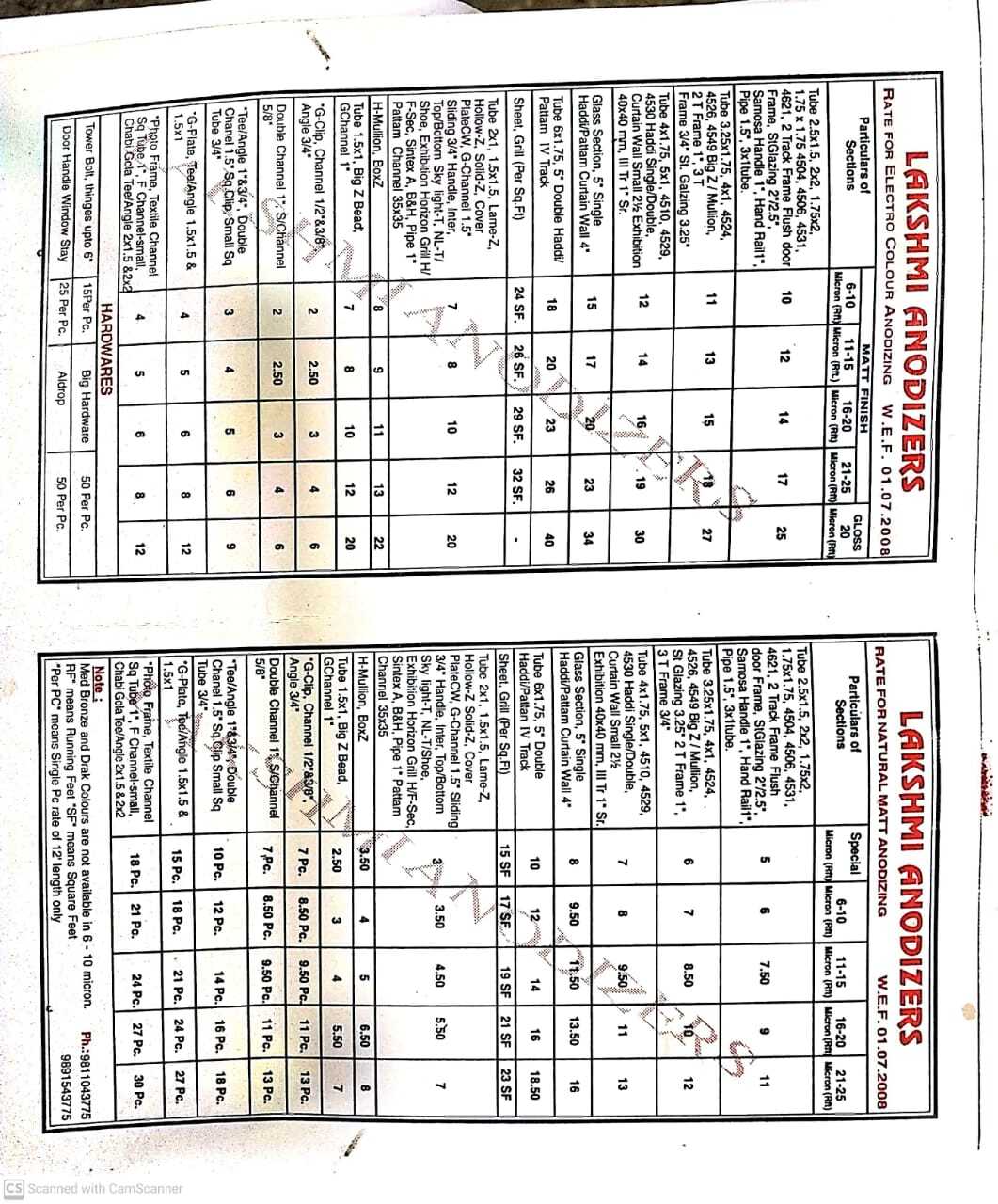

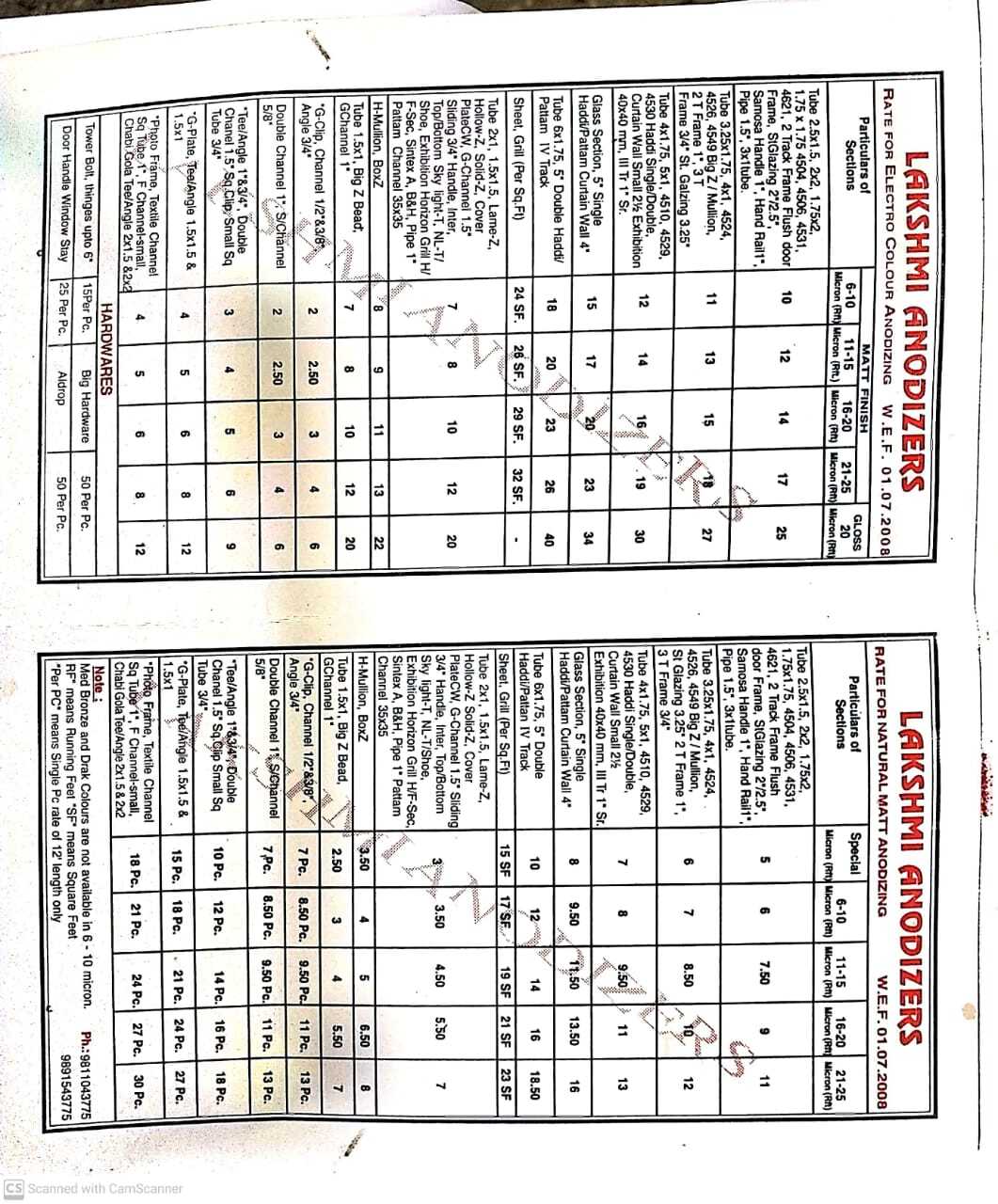

- Matte, Satin, Glossy

- Customization Available

- Yes

- Service Mode

- Offline

- RoHS Compliance

- Available on request

- Material

- Aluminium

- Anodizing Thickness

- 5-25 Microns (customizable)

à¤à¤²à¥à¤¯à¥à¤®à¤¿à¤¨à¤¿à¤¯à¤® à¤à¤¨à¥à¤¡à¤¾à¤à¤à¤¿à¤à¤ सरà¥à¤µà¤¿à¤¸à¥à¤ Trade Information

- Minimum Order Quantity

- 1 Tonne

- आपूर्ति की क्षमता

- 5000 प्रति महीने

- डिलीवरी का समय

- 7-10 दिन

- नमूना उपलब्ध

- Yes

- नमूना नीति

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

- प्रमाणपत्र

- MSME

About à¤à¤²à¥à¤¯à¥à¤®à¤¿à¤¨à¤¿à¤¯à¤® à¤à¤¨à¥à¤¡à¤¾à¤à¤à¤¿à¤à¤ सरà¥à¤µà¤¿à¤¸à¥à¤

We specialize in high-quality anodizing services, providing durable and corrosion-resistant finishes for a variety of metal products. Our state-of-the-art facilities and expert team ensure precise, reliable, and aesthetically pleasing anodized coatings tailored to your specific requirements. Partner with us for superior protection and enhanced visual appeal of your metal components.Q1: What is anodizing?A1: Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of metal parts, typically aluminum, to increase corrosion resistance, improve durability, and provide an aesthetically pleasing finish.

Q2: What metals can be anodized?A2: The most common metal for anodizing is aluminum, but other metals such as titanium and magnesium can also undergo the anodizing process.

Q3: What are the benefits of anodizing?A3: Anodizing provides several benefits, including enhanced corrosion resistance, increased surface hardness, improved wear resistance, and the ability to add vibrant colors to the metal surface.

Q4: What types of anodizing do you offer?A4: We offer various types of anodizing, including Type I (chromic acid anodizing), Type II (sulfuric acid anodizing), and Type III (hard anodizing) to meet different performance and aesthetic requirements.

Q5: How long does the anodizing process take?A5: The duration of the anodizing process depends on the size and complexity of the parts, as well as the type of anodizing. Typically, it ranges from a few hours to a full day.

Q6: Can anodized parts be colored?A6: Yes, anodized parts can be dyed in a wide range of colors. The porous nature of the anodized layer allows for the absorption of dyes, providing a variety of vibrant color options.

Q7: Is anodizing environmentally friendly?A7: Anodizing is considered environmentally friendly because it uses water-based processes and does not emit volatile organic compounds (VOCs). However, proper handling and disposal of chemicals used in the process are essential.

Q8: What surface finishes can be achieved with anodizing?A8: Anodizing can produce various surface finishes, including matte, satin, and bright finishes, depending on the pre-treatment and post-treatment processes applied.

Q9: How should anodized parts be maintained?A9: Anodized parts require minimal maintenance. Regular cleaning with mild soap and water, followed by rinsing and drying, is usually sufficient to maintain their appearance and performance.

Q10: What are the limitations of anodizing?A10: While anodizing provides many benefits, it may not be suitable for all applications. It is primarily limited to aluminum and certain other metals and does not provide significant protection against heavy mechanical wear or impact.

Tailored Anodizing Solutions for Every Industry

We specialize in adapting our aluminium anodizing services to fit a variety of sectors, whether you need enhanced durability for automotive parts or decorative finishes for architectural elements. With the ability to customize thickness and color, our processes cater to the specific demands of each client, ensuring both functionality and aesthetic appeal for every application.

Exceptional Durability and Corrosion Resistance

Our anodizing treatments significantly improve aluminium's performance, providing a tough, corrosion-resistant surface. The protective layer is locked into the metal structure itself, delivering extended lifespan and reduced maintenance. Choose from matte, satin, or glossy finishes-all with outstanding adhesion and resistance to wear.

Flexible Process and Swift Turnaround

We understand that project timelines vary, which is why our anodizing process duration is tailored between 1 and 7 days depending on your workload and specifications. Our state-of-the-art facility accommodates components up to 3 meters, and we maintain high efficiency to ensure your components are delivered on schedule.

FAQ's of Aluminium Anodizing सेवाएं:

Q: How is the anodizing thickness customized for different applications?

A: The anodizing thickness can be tailored between 5 and 25 microns, allowing us to match the specific durability and appearance requirements of diverse applications, from decorative elements to heavy-duty industrial parts.Q: What color and finish options are available for aluminium anodizing?

A: We offer matte, satin, and glossy finishes in standard colors like natural, black, and gold. Bronze, blue, and red are available upon request, providing clients with ample choices to suit their design or branding preferences.Q: Where are the anodizing services provided and what is the maximum size component you can process?

A: Our services are available Pan India, and we are equipped to anodize aluminium components up to 3 meters in length, depending on the capabilities of our facility.Q: What benefits does aluminium anodizing offer for architectural or industrial use?

A: Aluminium anodizing enhances corrosion resistance, increases surface durability, and provides a long-lasting, decorative appearance. This makes it ideal for architectural facades, industrial machinery parts, and automotive components exposed to environmental stress.Q: What is the typical process duration for anodizing, and is RoHS compliance offered?

A: The anodizing process typically takes 1 to 7 days, depending on the complexity and volume of the order. RoHS-compliant anodizing is available on request to support environmentally responsible manufacturing.Q: Can I request custom finishes or colors for large orders?

A: Yes, we provide customization options for both finishes and colors-including special hues like blue and red-especially for large or specialized orders. Please consult our team for specific requirements and feasibility.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in एनोडाइजिंग सेवाएँ Category

एल्युमिनियम कलर्ड एनोडाइजिंग सर्विसेज

मूल्य या मूल्य सीमा : आईएनआर

मूल्य की इकाई : किलोग्राम/किलोग्राम

न्यूनतम आदेश मात्रा : 10

माप की इकाई : किलोग्राम/किलोग्राम

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें